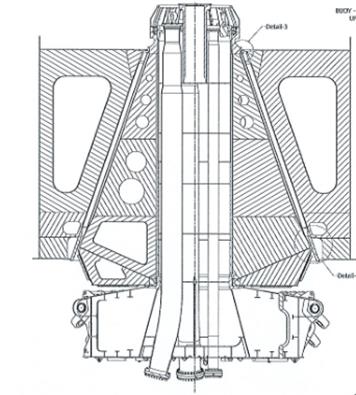

Our team has finally completed the detachable turret mooring FPSO refurbishment project in China after several rounds of technical discussion on the methodology and re-schedule of docking. The 9000mm diameter mating surface tolerance (circularity and dimensions) of a submerge turret is important to guide the buoyancy cone into the FPSO.

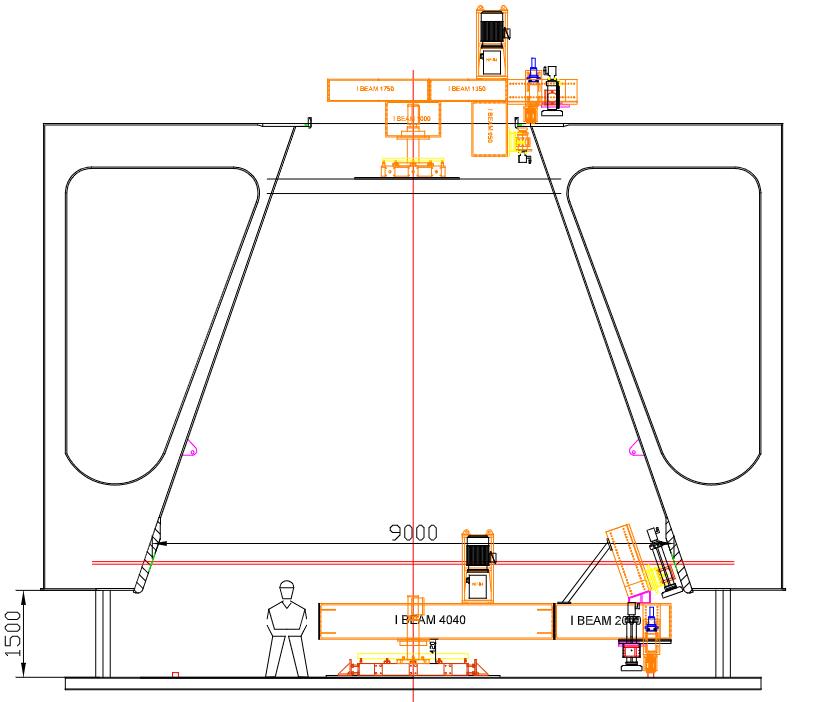

In order to conduct the machining in dry-dock, a temporary support structure was specially designed and fabricated to attach at the bottom of the hull. This act as a working platform to hold our portable circular milling machine and personnel to carry out the precision machining on the tapered cone shaped module.

With the vast experience gathered from prior new build machining project in detachable turret mooring system, our field service specialists are able to execute the project swiftly at site, achieved the required tolerance and help our client to reduce the critical path to generate more float period for other refurbish scope.