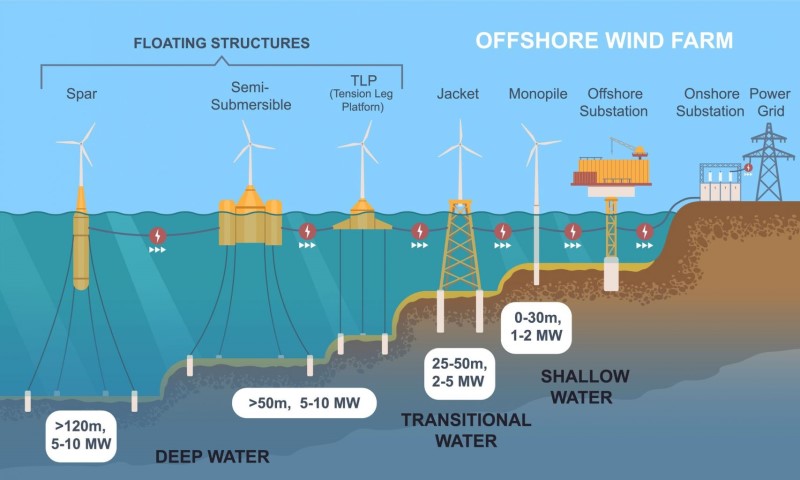

Offshore wind turbines are crucial for harnessing the power of wind over bodies of water, providing a significant source of renewable energy. The installation process varies depending on the water depth, environmental conditions, and turbine size. Below are the main types of offshore wind turbine installation:

Fixed-bottom wind turbines are anchored to the seabed and are the most common type of offshore wind turbine installation. They are typically used in shallow to moderately deep waters, where the foundation can be securely attached to the seabed.

Machining scope of monopoles and jackets

Machining for monopiles and jackets typically involves precision work on large-diameter steel pipes and the components that connect the monopile to the transition piece and turbine tower.

The transition piece is a crucial part of offshore wind turbine structures, serving as the intermediary between the foundation and the tower. The transition piece is typically installed on top of the foundation (monopile or jacket) and forms the base for the wind turbine tower. It is designed to align perfectly with both the foundation and the tower, allowing for a smooth and strong connection between the two. The transition piece helps correct any small misalignments between the foundation and the turbine tower.

The flanges that connect the monopile and jackets to the transition piece must be machined to exacting standards. Flatness and smoothness of the flange surfaces are crucial to ensure a perfect fit and prevent structural issues over time. To provide smooth seating for bolt heads, spot facing around drilled holes may be required to ensure proper load distribution.