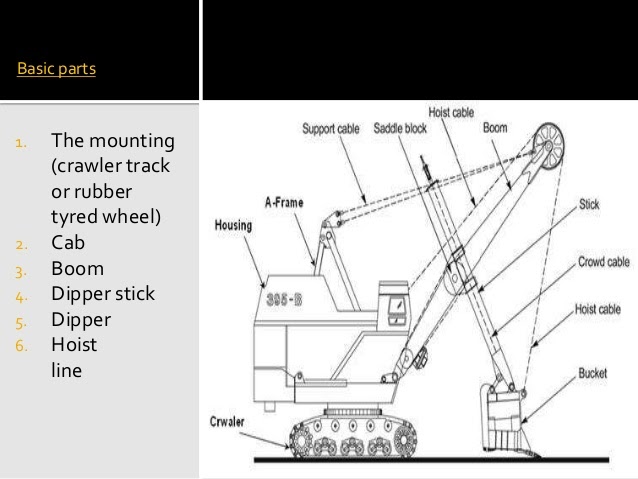

Heavy construction equipment, such as excavators like draglines and shovels, play a crucial role in mining and bulk material handling operations. These powerful machines consist of a boom, dipper (or stick), bucket, and cab, all mounted on a rotating platform known as the “house.” This house sits on top of an undercarriage equipped with either tracks or wheels, allowing for mobility and efficient operation.

Similarly, stackers and reclaimers are essential machines in bulk material handling. A stacker piles bulk materials such as limestone, ores, or cereals onto stockpiles, while a reclaimer retrieves these materials from the stockpile for use in processing or transport. These machines are critical to operations in industries like mining, agriculture, and construction.

The Importance of In-Situ Machining for Heavy Equipment

Given the remote locations of many mines and bulk material handling sites, along with the massive size and bulk of these machines, transporting defective components to an off-site repair facility can be both costly and time-consuming. This is where in-situ machining becomes invaluable.

In-situ machining refers to performing precision machining operations directly at the worksite, eliminating the need for dismantling and transporting equipment. This approach offers several key benefits:

- Minimized Downtime:

By conducting repairs on-site, the downtime associated with transporting and reassembling equipment is drastically reduced, helping to keep your operations running smoothly. - Cost Savings:

Avoiding the logistics and transportation costs involved in moving large, heavy equipment saves both time and money, especially in remote mining locations. - Reduced Equipment Dismantling:

In-situ machining eliminates the need to dismantle auxiliary equipment connected to the defective components, further reducing time and labor costs.

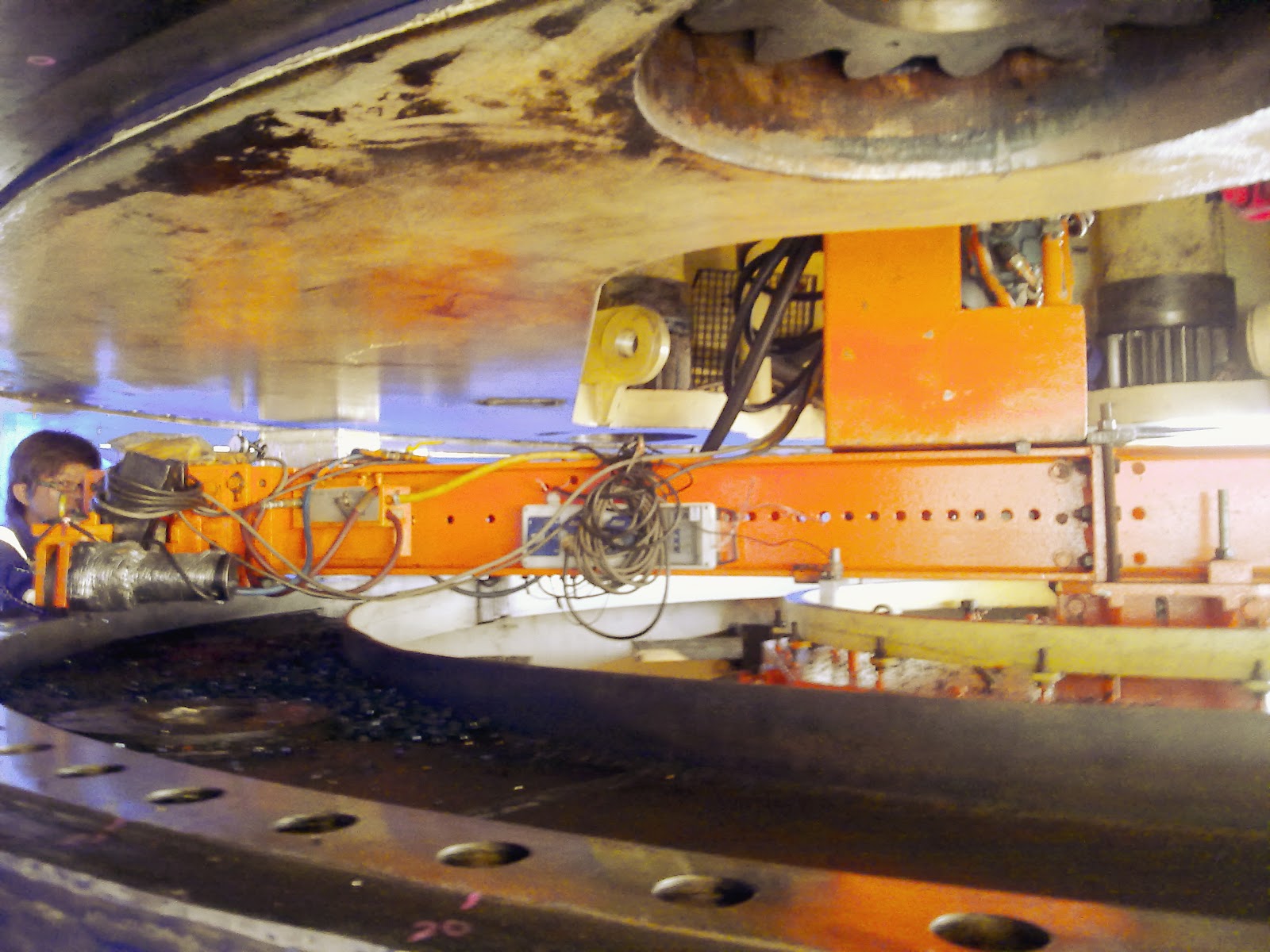

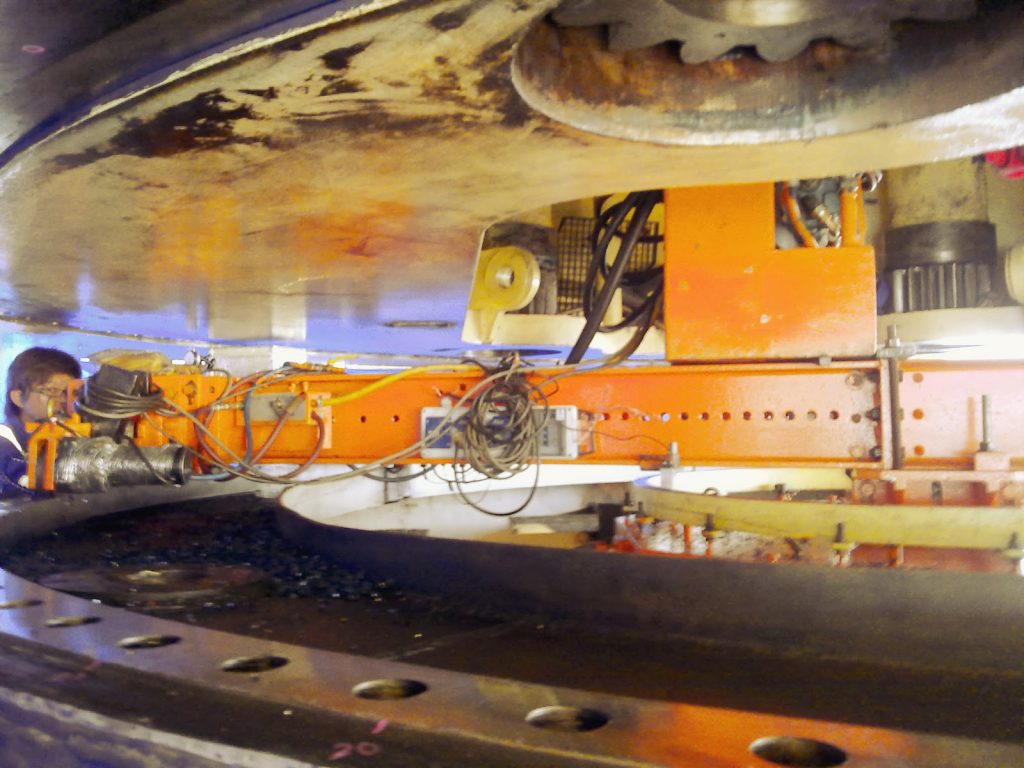

Machining of stacker & reclaimer

We understand the specific challenges posed by the bulk material handling industry, and we tailor our in-situ machining solutions to meet the unique requirements of each project. Whether you’re dealing with equipment at a mining site or handling bulk materials at a port or industrial facility, our experienced team is equipped to handle the job.

(1)

Machining of Excavator

At our company, we specialize in in-situ machining services for a wide range of heavy construction and material handling equipment, including excavators (draglines and shovels), stackers, and reclaimers. Our precision machining services ensure that your critical equipment is repaired efficiently and restored to peak performance without the need for costly transportation.

(3)

(1)

In industries such as construction, mining, and material handling, heavy equipment operates under extreme conditions. The harsh working environment and continuous heavy loads lead to frequent wear and tear, especially in areas that rely on rotational movements like slew bearings, carriages, and booms. Regular maintenance and precision installation in these areas are essential to avoid costly breakdowns and maintain the structural integrity of your equipment.

Common Issues: Wear and Tear on Rotational Components

High levels of stress and repetitive rotational movements often cause significant wear on key components, including:

- Slew Bearings:

These components are critical for smooth rotational movement in large machinery like cranes, excavators, and stackers. Excessive wear on slew bearings can drastically reduce their lifespan, leading to potential equipment failure. - Carriages and Booms:

Continuous rotational operations put stress on the carriage and boom, making them susceptible to cracks, misalignment, and eventual failure if not properly maintained.

The Importance of OEM-Specified Maintenance

To ensure the long-term reliability of slew bearings, shafts, pins, and bushes, all installation and maintenance activities must strictly follow the specifications outlined by the Original Equipment Manufacturer (OEM). Meeting OEM standards guarantees that these essential parts function at their highest capacity, reducing the risk of damage and prolonging equipment life.

- Structural Integrity:

Proper maintenance of slew bearings and swivel parts is vital for preventing structural failures like cracking in the carriage and revolving frame. Ensuring the alignment and performance of these parts is critical to your equipment’s ability to handle heavy loads. - Extended Service Life:

Adhering to OEM specifications during maintenance helps extend the service life of rotational components, reducing the need for frequent repairs or replacements and enhancing operational efficiency.

Why Choose Our In-Situ Machining Services?

- Expertise in Heavy Equipment:

We specialize in servicing slew bearings, carriages, booms, and other critical rotational components for industries such as mining, construction, and material handling. - OEM-Approved Solutions:

Our in-situ machining services ensure that your repairs and installations meet the strictest OEM standards, guaranteeing the longevity of your equipment. - Reducing Downtime:

By offering on-site machining, we minimize equipment downtime, keeping your projects on schedule and reducing the risk of extended operational delays.

For reliable, cost-effective, and time-efficient in-situ machining solutions, trust our experienced team to maintain and restore your slew bearings, carriages, and booms. With our focus on precision and OEM compliance, we help protect your equipment’s structural integrity and ensure optimal performance in demanding environments.