Floating Production Storage and Offloading vessels (also known as FPSOs), are offshore production facilities that house both processing equipment and storage for produced hydrocarbons. The basic design of most FPSOs encompasses a ship-shaped vessel, with processing equipment onboard the deck and hydrocarbon storage below in the double hull which are offloaded periodically to shuttle tankers or transmitting via pipelines.

FPSOs are ideal for developing both deepwater and ultra-deepwater oil fields, providing a flexible and cost-effective solution for offshore production. Depending on field requirements, FPSOs can be equipped with either a central mooring system—allowing the vessel to rotate in response to weather conditions—or spread-mooring systems, where the vessel is anchored at multiple points on the seafloor to enhance stability.

A spread mooring system features a fixed orientation, making the vessel more sensitive to environmental factors like wave intensity and direction. Due to its fixed position, vessels with this system are susceptible to waves hitting at larger angles, increasing the likelihood of substantial vessel motions, particularly roll movements. This can present challenges in harsher marine environments.

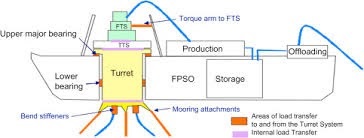

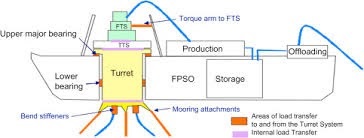

On the other hand, a central mooring system utilizes a turret column secured to the seabed with anchor lines. The turret is integrated into the FPSO’s structure, allowing the vessel to weathervane freely, meaning it can rotate to face the least resistance from waves, wind, and currents. This design minimizes vessel motion, ensuring more stable operations. Additionally, disconnectable turret mooring systems offer a safety feature that enables FPSOs to detach quickly from their moorings and risers in extreme environmental conditions, such as hurricanes, typhoons, or icebergs in regions like the Gulf of Mexico or the South China Sea.

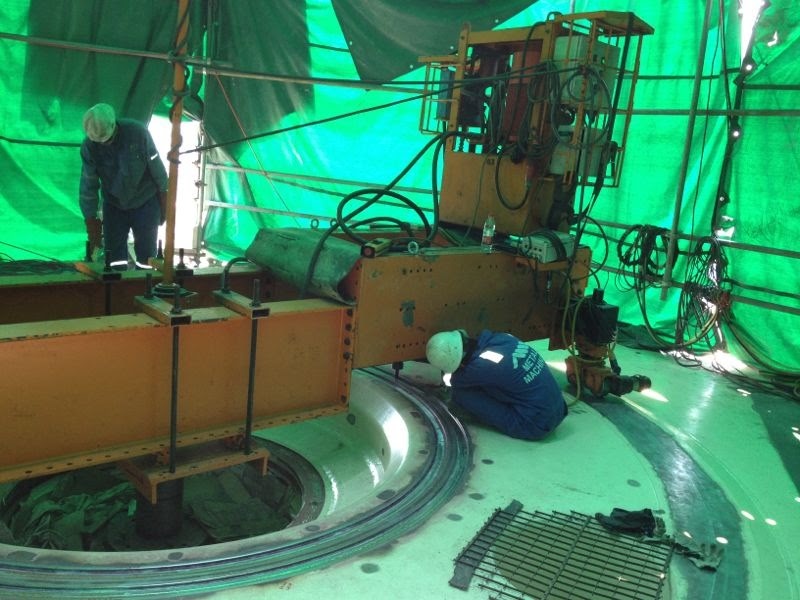

Machining scope for Internal turret mooring system

(1)

Machining scope for detachable turret mooring system

(1)

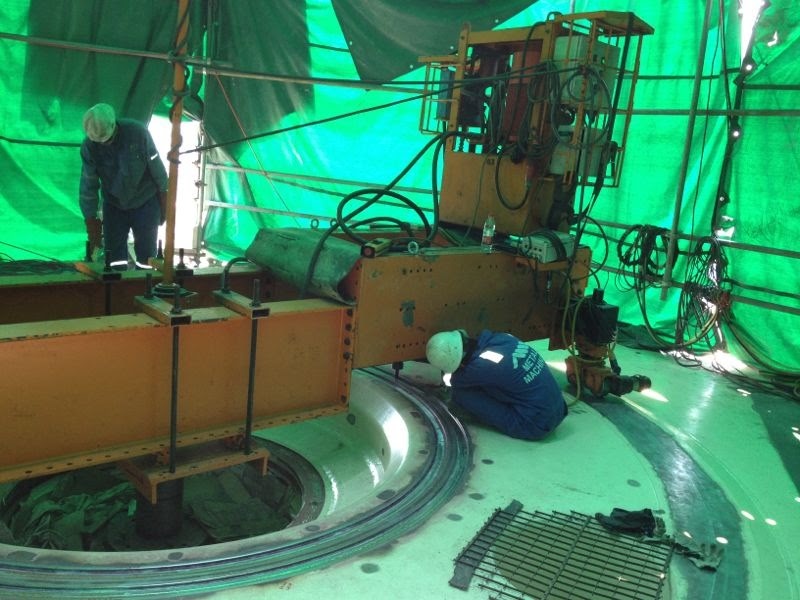

Since 2000, SLMM has proudly specialized in FPSO turret machining, gaining invaluable experience across various mooring designs. As the demand for increased capacity rises, the turret sizes have expanded significantly, from a mere 5 meters in diameter to an impressive 40 meters, as seen in the Prelude FPSO. This evolution has led to the incorporation of intricate machining profiles and the use of advanced materials like Inconel 625 and stainless steel 316L, which offer superior wear and corrosion resistance.

Our commitment to innovation drives us to continuously develop and refine our in-situ machining methodologies. By collaborating with leading tooling partners, we consistently deliver results that meet the high standards of the industry. Our technical expertise has garnered recognition, resulting in invitations from FPSO designers to contribute to new turret designs, further solidifying our reputation in the field.

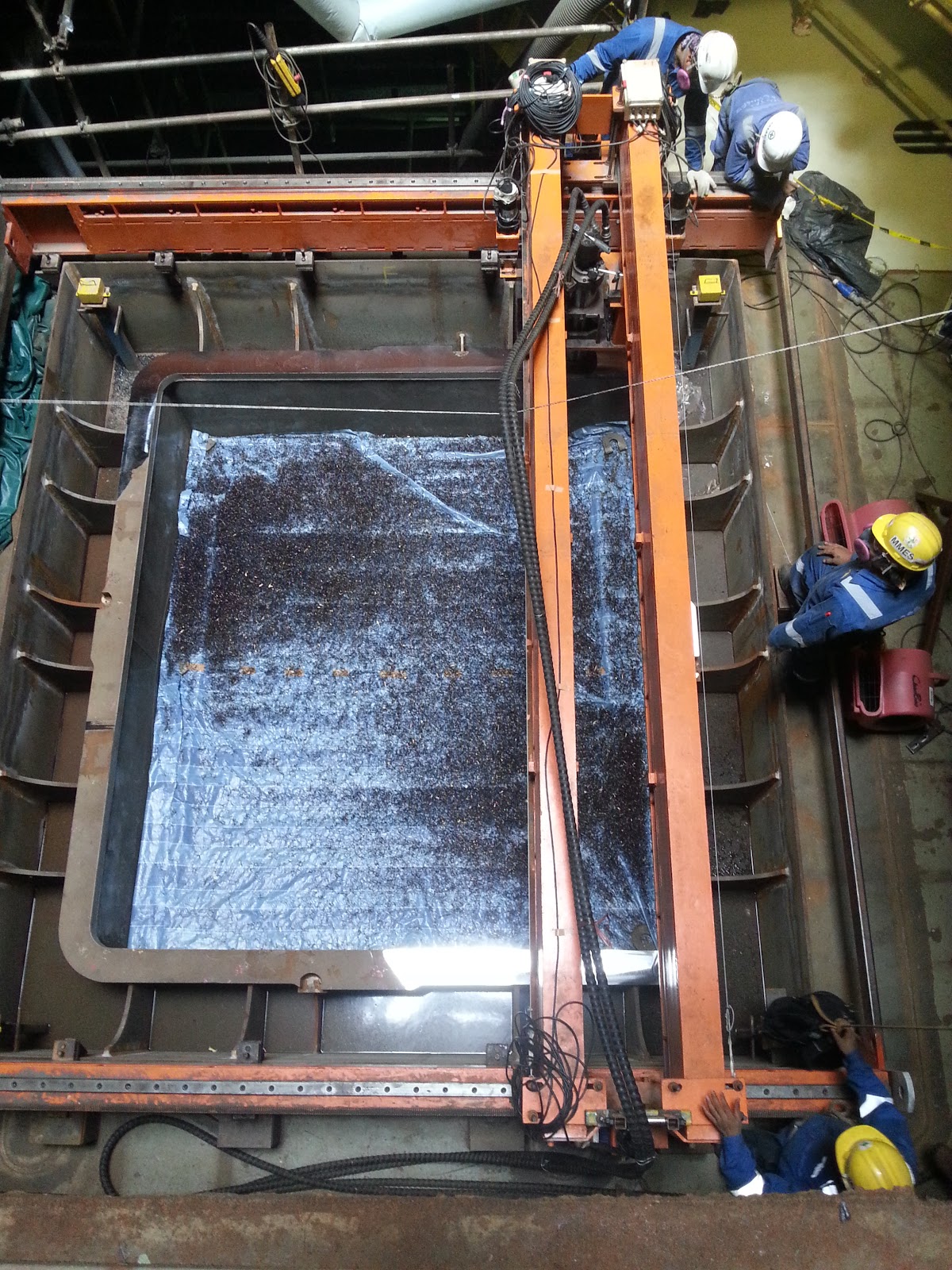

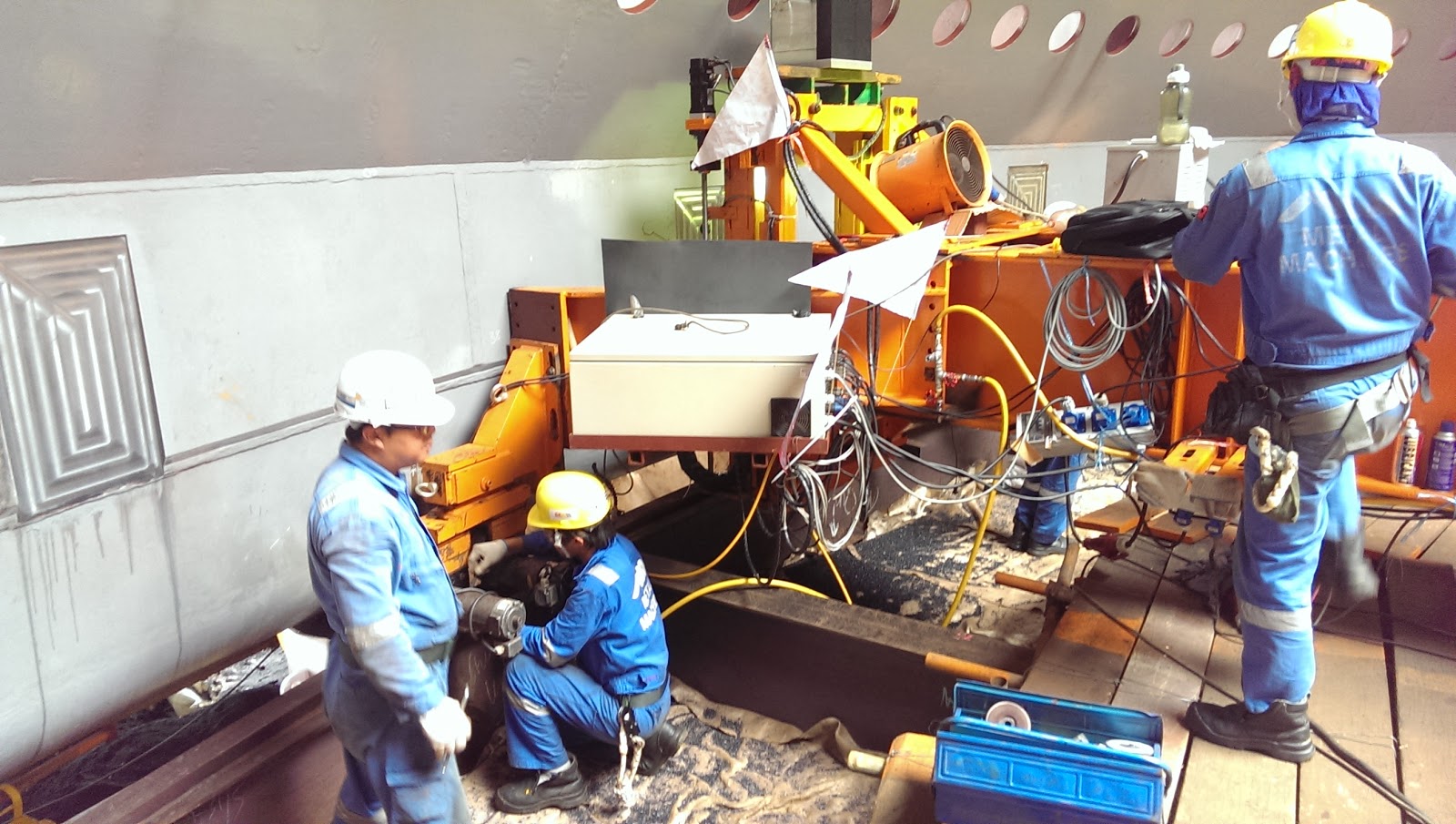

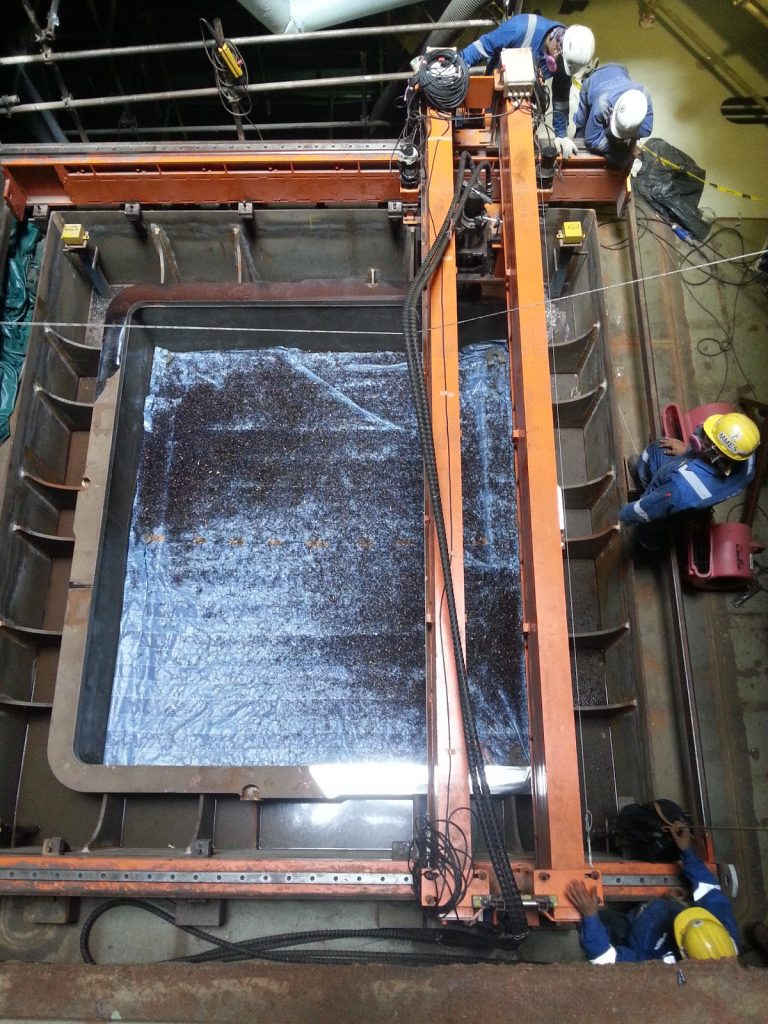

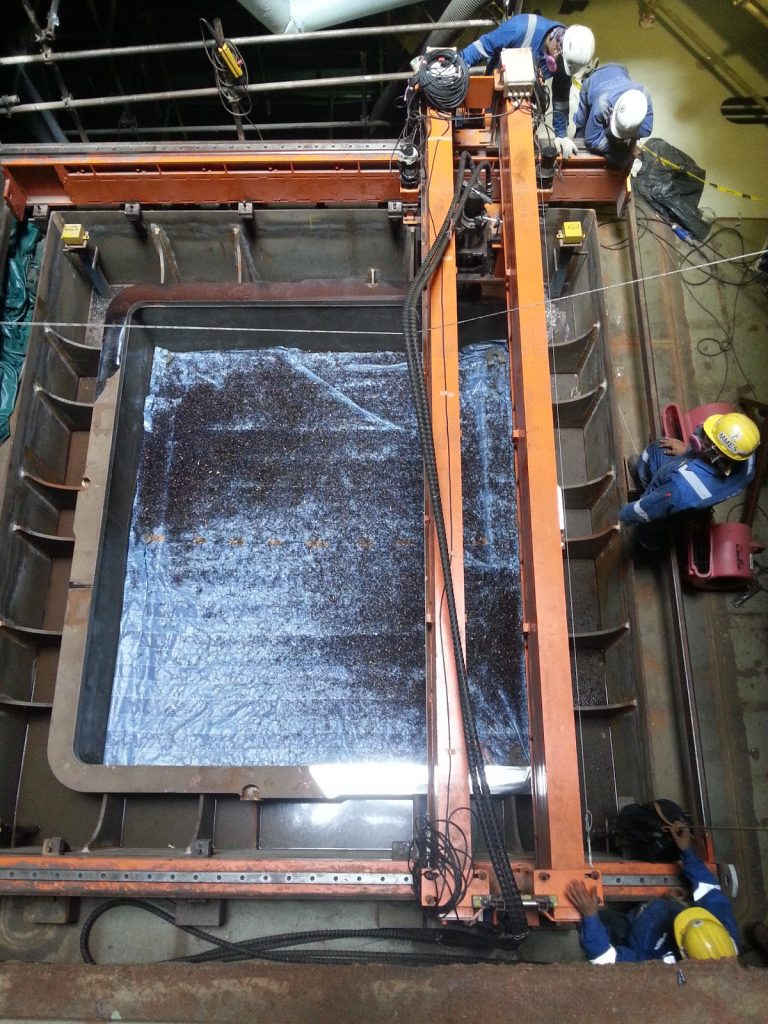

Full machining of mating area of a detachable buoyancy cone

Measurement of Inconel overlay journal bearing using PI tape

FPSOs are effective development solutions for both deepwater and ultra-deepwater fields. It can either adopt a central mooring system which allows the vessel to rotate and respond to weather conditions, or spread-mooring systems which anchor the vessel from various locations on the seafloor.

Spread mooring system has a fixed orientation which make the vessel more sensitive to global environment intensity and direction. This makes the vessel susceptible to waves incident at large relative wave angles, increasing the probability for substantial vessel motions, especially roll.

Central mooring system comprises a fixed turret column held by an internal or external vessel structure via a bearing arrangement. The vessel can weathervane freely around the turret which is fixed to the seabed via a number of anchor lines. Such arrangement allows the FPSO to adopt the direction of least resistance against waves, wind, and currents. There is disconnectable turret mooring system which allow FPSO to disconnect fast from their moorings and risers to avoid dangerous environmental conditions such as icebergs, hurricanes in the Gulf of Mexico or typhoons in the South China Sea.

Machining scope for Internal turret mooring system

(1)

Machining scope for detachable turret mooring system

(1)

SLMM has the privilege to involve in FPSO turret machining since year 2000 and given the opportunities to work on different mooring design. To accomodate more riser pipes with increase capacity, turret’s size has increased from 5m in diameter up to 40m (Prelude FPSO) and incorporated intricate machining profile. Diverse material usage such as inconel 625 and stainless steel 316L are also becoming commonly used for higher wear and corrosion resistance.

These developments propel us to continue innovate and devise in-situ machining methodology by working with tooling partners to deliver the expected results. Our efforts eventually conceive the invitation from FPSO designer to participate in new turret design, which is a recognition to our technical capability.

Full machining of mating area of a detachable buoyancy cone

Measurement of Inconel overlay journal bearing using PI tape