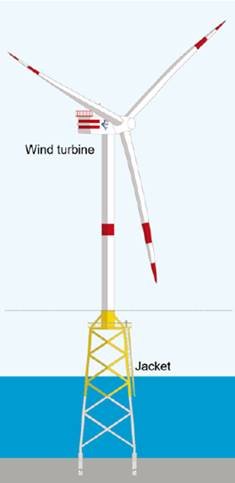

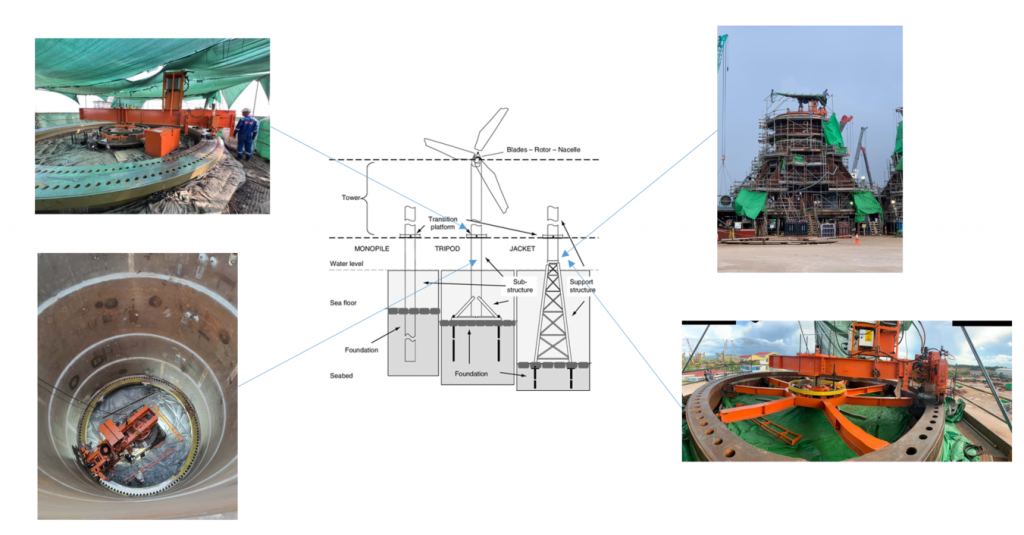

The foundation of an offshore wind turbine—whether a monopile, jacket, or floating structure—requires precise machining to ensure structural integrity, seamless fit-up, and long-term durability in harsh marine environments. Achieving tight tolerances in flatness, surface roughness, and hole alignment is critical for optimal load distribution, reducing the risk of bolt fatigue, misalignment, and premature failure.

Transition Piece (TP)

The interface between the monopole/ jacket and transition piece (TP) demands high precision in flatness, surface roughness, and hole alignment to ensure a secure bolted or grouted connection. As the second part of a Wind Turbine Generator (WTG) foundation, the transition piece directly connects to the monopile, providing a critical link to the turbine tower.

Once installed, the transition piece is bolted and reinforced with grout, allowing for adjustments to compensate for any misalignment caused during monopile installation—since perfect verticality cannot be guaranteed after pile driving. To enhance visibility at sea, the transition piece is painted yellow post-installation.