Metrology and Surveying

Over the years in providing field machining, one of the major delay factors is due to insufficient material to machine and meet the GD&T requirement. This is mainly caused by structural distortion or inadequate fabrication quality. By upskill our services to analyse measured data on the as built condition, we are able to highlight clients on potential problems and derive corrective actions before machining. To cater for different needs, we have continuously keeping abreast with in situ metrology development, consistently invest in equipment and training for our field specialist. The equipment and software that we have invested are:

(a) 2 set of Leica TM30 Total Station

TM30 is used to capture the overall condition of a big assembly as it has long range surveying capability (more than 100m) and able to gather data without the need of a reflector. This minimise the cost of erecting staging and time to physical move around the structure. The general accuracy range between 0.5mm to 2mm *depending on distance and usage of reflector.

(b) 2 set of Laser Tracker (FARO Vantage and API Omnitrac 2)

Laser tracker has measurement range up to 50m and is mainly used for checking GD&T of a component with accuracy up to 0.02mm *depending of measurement distance. Unlike a total station, the usage of this equipment need a Spherically Mounted Retroreflector (SMR) Ball Probes hence need access to the area of interest.

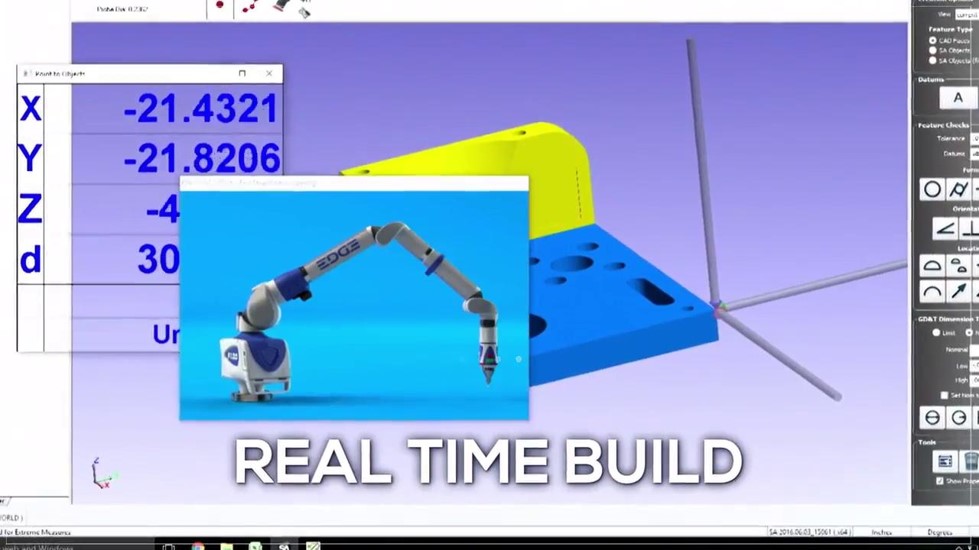

(c) 1 set of FARO Edge CMM arm

12ft FARO Edge arm has a volumetric accuracy up to +/-0.091mm with single point repeatability up to 0.064mm.

(d) 2 set of Spatial Analyser license

It is an instrument-independent, traceable 3D graphical software platform that is able to integrate data from multiple instruments and perform analysis. SA can simultaneously communicate and integrate data from Laser Trackers, Portable CMM, Total Stations and Laser Scanners.